Scheduled maintenance can dramatically reduce the disruption of unexpected maintenance and help maximize the value of your assets. Performing maintenance at pre-planned intervals decreases the likelihood of costly breakdowns and gives you time to coordinate around the downtime.

But that coordination takes effort, and whatever your preventive maintenance plan, it only works if you keep the pieces moving. Tango Maintenance simplifies the process by giving you a purpose-built framework for building out your plan. You define the schedule, steps, and stakeholders, and Tango helps you keep it on track with notifications and straightforward workflows.

In this article, we’ll outline some of the major challenges organizations have with scheduled maintenance. Then we’ll share how Tango Maintenance addresses these issues and equips facility managers to effectively facilitate scheduled and preventive maintenance programs.

Scheduled maintenance challenges

Planning maintenance work in advance helps organizations maximize the value of their assets by reducing breakdowns and keeping performance high. But while scheduled maintenance is simple in principle, it’s far more difficult in practice. As the volume and complexity of assets increase, so does the operational overhead and required work. This can make it hard for companies to reap the benefits of their preventive maintenance plans throughout their portfolios.

Lack of asset visibility

Arguably the greatest challenge with creating and following maintenance schedules is that most facility managers don’t know what and where all their assets are, let alone when and how they need to be maintained. This is simply a result of the sheer number of assets that can be associated with modern facilities. A single building could have hundreds or even thousands of assets that each have their own work order history, manufacturer warrantees and guidelines, and compliance requirements—and that information is often scattered across physical locations, spreadsheets, and disconnected digital systems.

Centralizing your asset data is crucial to implementing a preventive maintenance plan. Each maintenance schedule has to be designed around the specific circumstances of the given asset, and that information needs to flow into work orders and other documentation so maintenance personnel and vendors can follow the schedule. Tango Maintenance intakes all of your asset documents and history, and organizes them in intuitive ways, so you can easily build and follow relevant maintenance schedules.

Prioritizing work orders

At any given time, your maintenance personnel are bound to have more work in the queue than they can complete. They’re continually evaluating the risk associated with each asset and job to determine which work orders are first in line, and which ones need to be deferred. Scheduled maintenance, as a preventive measure, is easier to delay than ad hoc work that arises on demand—especially if work orders for scheduled and unscheduled maintenance aren’t visible in the same place.

Maintenance leads need visibility into upcoming work and enough contextual information to appropriately prioritize scheduled maintenance. Tango Maintenance separates demand work orders and scheduled maintenance work orders, but keeps both categories of work order visible from the same dashboard. And whether you created it months ago as part of a maintenance plan or you created it today, your team can see any relevant information you associate with the job.

Coordinating with external vendors

Some assets and types of work require specialists. Your personnel may not have the certifications or expertise, or perhaps a Service Level Agreement (SLA) requires the work be performed by a specific vendor. In any case, in order for preventive maintenance to work at scale, your system needs to incorporate external professionals and coordinate with their schedules.

Additionally, you want to ensure that when service providers perform maintenance on your assets and infrastructure, they follow any protocols your operations require and document the work according to your standards. They need access to your maintenance system—but only the parts of it that relate to the specific work order they’re completing.

Tango Maintenance lets you assign scheduled maintenance work orders to a vendor in advance, and gives them the limited access they need to access relevant documents and complete the work according to your protocols.

Now let’s look at how easy it is to produce maintenance schedules in Tango.

Managing your scheduled maintenance with Tango

Tango Maintenance is a dedicated facility maintenance solution designed to address the biggest challenges with large-scale maintenance operations, including scheduling, coordinating, and executing your maintenance plans.

Creating a scheduled maintenance plan

At any given location, a facility manager may need to coordinate maintenance for dozens, hundreds, or even thousands of assets, including building infrastructure and equipment. Tango makes it easy to create maintenance schedules for specific assets in specific locations.

Creating maintenance plans in Tango is a simple process. Follow a guided workflow to organize your plan within the system, ensure it’s associated with the right people and assets, and define what the actual work orders will look like when the schedule is activated. You’ll be prompted to provide information in three steps.

1. General information: Name the plan, describe it, set the frequency (recurrence), and specify “days before due to activate”—in other words, when to create the work order for the scheduled work.

2. Places/Things: Identify the location(s) and asset(s) the plan applies to, associate the plan with a specific facility manager and a “provider” (internal maintenance professional or external vendor), and attach any relevant maintenance documents, such as Service Level Agreements and plan documents.

3. Scope: Define the notification schedule and what they’ll include (text, images, links, etc.) and create a questionnaire for the work order if applicable for checklists, file uploads, etc.

Tango includes work order templates and questionnaire templates to help speed up the process.

In one of their sessions at Tango Connect, Director of Product Strategy, Arin Capellari and Senior Manager of PMO, Joel Johnson showcased Tango’s suite of Scheduled Maintenance features. You can access their presentation here.

Generating scheduled maintenance reports

Well-run preventive maintenance plans help you avoid surprises and operational disruptions—they should enable you to coordinate the work that needs to be done, even as new work comes in on-demand. So it’s essential that your maintenance team has visibility into maintenance schedules. If maintenance leads feel like work orders are suddenly appearing from within the system, or they can’t tell when a scheduled work order is waiting for action from them, you lose the benefits of scheduling the work in advance.

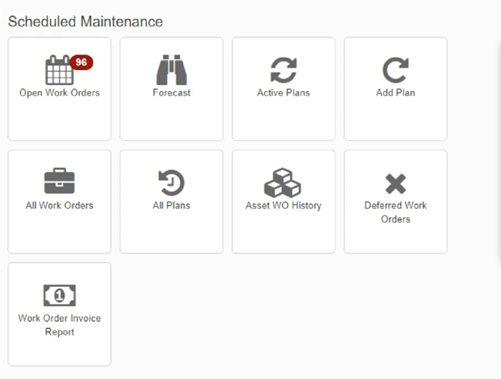

Once a facility manager has created a maintenance plan in Tango Maintenance, maintenance leads can review upcoming scheduled maintenance, unassigned scheduled maintenance work orders, and open scheduled maintenance work orders.

Control access and collaborate with external vendors for scheduled maintenance

Tango Maintenance lets you provide trusted vendors with limited access to the system, enabling them to see and complete work orders you’ve assigned to them. This helps ensure that third-party service providers submit documents according to your standards and follow your specifications, and keeps work organized in the same system, regardless of who completes it.

Whether you’re scheduling internal maintenance or work for a vendor, Tango helps route it to the right person at the right time, provides the right steps, and keeps information in the right place—all according to your schedule.

Keep maintenance on track with Tango Maintenance

Scheduled maintenance is a crucial component of modern facility management. Tango makes it easy to create, implement, and track your planned work by keeping scheduling workflows and the relevant information organized in a single cohesive, consistent system.

Request a demo of Tango Maintenance to see a better way to coordinate scheduled maintenance and keep your assets in peak condition.